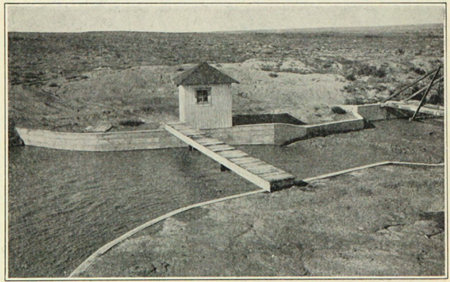

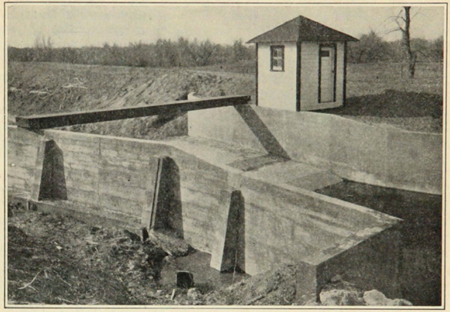

In North America, large Parshall Flumes – those with throat widths larger than 144-inches – are primarily used to measure the diversion of water from streams, lakes, and other primary sources of surface water to smaller irrigation distribution systems. Most of these installations are in the Intermountain region where the importance of water rights is far higher (and more regulated) than in other area.

Large Parshall flumes are not commonly used in wastewater applications due to the limitations of fiberglass construction (more below) and the potential for biogenic / Microbial Induced Concrete Corrosion (MICC), where hydrogen sulfide is converted into sulfuric acid by microbes, in concrete construction. For these applications, Parshall flumes up to 144-inches in size are used – in parallel channels if more flow capacity is needed.

Dimensions

For throat sizes from 15-feet to 50-feet:

- The length of the inlet of the flume only increases by 2-feet [60.96 cm] (from 25-feet long to 27-feet)

- The throat length is constant at 6-feet [182.9 cm] long

- The location of the secondary point of measurement, Hb, is the same

- The sidewall height is the same, 6-feet [182.9 cm] high, for throat widths from 20-feet to 50-feet

- There are no recommended inlet radius wing walls

MASTER DIMENSIONS FOR LARGE PARSHALL FLUMES

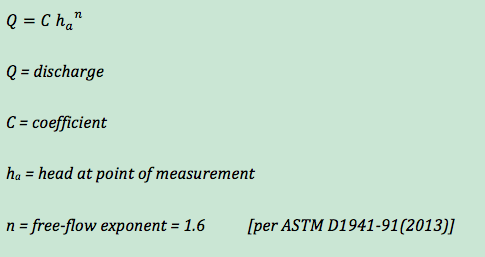

Discharge Equations

The free-flow discharge equations for large Parshall flumes are expressed as:

| Size | C (Q=CFS) | C (Q=L/S) |

| 15-Feet | 57.81 | 6.912 |

| 20-Feet | 76.25 | 9.117 |

| 25-Feet | 94.69 | 11.32 |

| 30-Feet | 113.13 | 13.53 |

| 40-Feet | 150.00 | 17.94 |

| 50-Feet | 186.88 | 22.35 |

Submergence Transition

Per ASTM D1941-91(2013), the submergence transition for large Parshall flumes is 80%. At, and above, this point and the submerged flow discharge equation must be applied – which in turn require that two head measurements be taken (at the Ha – primary – and Hb – secondary – points of measurement).

From a practical standpoint, 90% should be the maximum submergence that should be viewed as correctable. Greater than 90% and very minor errors in determining Ha or Hb can dramatically affect the calculated flow rate.

Construction

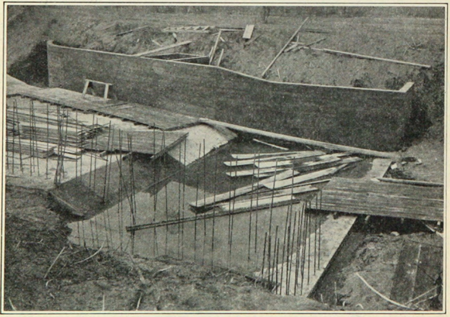

Large Parshall flumes are almost always made from concrete. The costs of even temporary molds rule out fiberglass construction for flumes larger than 15-feet, while metal constructed flumes require a considerable amount of to try to move and install.

If concrete is used, it is important that the forms should be carefully set to insure exact dimensions.

As a result, large Parshall flumes are site fabricated with temporary forms. Off-site, pre-cast construction is possible, but like large metal flumes, the costs to transport and install them are considerable.

Sources: Parshall, R., Parshall Flumes of Large Size, Bulletin 386, Colorado Experiment Station, Colorado Agricultural College, May, 1932, ASTM D1941-91(2013) - Standard Test Method for Open Channel Flow Measurement of Water with the Parshall Flume, Skogerboe, G., Hyatt, M., England, J., Johnson, J., Measuring Water with Parshall Flumes, WRG-4, EC-323-, Utah Water Research Laboratory, Utah State University Extension Services, 1966