A Packaged Metering Manhole (PMM) is a factory-integrated fiberglass manhole that mounts a flume, weir, mag meter, or other primary device to allow a user to measure or sample flows from full or non-full pipes.

A Packaged Metering Manhole (PMM) is a factory-integrated fiberglass manhole that mounts a flume, weir, mag meter, or other primary device to allow a user to measure or sample flows from full or non-full pipes.

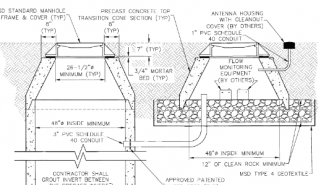

Components of a Metering Manhole

At its most basic a Metering Manhole consists of:

- Manhole tube

- Top

- Primary device (flume, weir, mag meter)

- End connections (pipe stubs or flanges)

- Base

The manhole tube can also be supplied with a range of accessories, including: access ladders, vents, benching, cabling couplings, shelfs, and operator platforms.

Depending upon the primary device, stilling wells, flow meter mounts, gratings / covers, and other accessories can be mounted.

How to Install a Packaged Metering Manhole

Metering Manholes are extremely easy to install:

Metering Manholes are extremely easy to install:

- Excavate the site, exposing the line the manhole it to be connected to.

- Pour a concrete pad

- Divert / stop flow through the line

- Cut the line

- Lower the manhole onto the pad

- Connect the manhole stubs / flanges to the line

- Secure the manhole to the pad

- Backfill the excavation

For a step-by-step walkthroughs on how to install a metering manhole, take a look at:

Installing a metering manhole is a simple as Dig It! Drop It! Done!

Metering Manhole Advantages

Depending upon whether you are a consulting engineer, installing contractor, or operator, Packaged Metering Manholes have a number of distinct advantages over other flow metering approaches.

In general, the advantages are:

- Single-Source Responsiblity

- The primary device is factory integrated into the manhole - no finger pointing between subcontractors.

- Accuracy

- Properly installed primary devices (and reduced inflow) mean that accurate measurements can be taken

- Longevity

- Installed lifespans are typically 25+ years

- Reduced inflow

- Measure and quantify only the flow going through pipe - not that spilling into the manhole

- Environmental

- Watertight, corrosion resistant construction makes it unlikely that a metering manhole will ever experience a spill or leak due to failure of the structure

- Economics

- Higher initial material cost is more than off-set by installation and life-cycle costs

- Usability

- Packaged Metering Manholes are highly customizable - allowing operators to configure them for maximum usability. They require little more than a periodic wash down to maintain them. They provide excellent operator access entering / exiting the manhole as well as working inside with the primary device.

Metering Manhole Drawbacks

The only true drawback to a Packaged Metering Manhole is the higher upfront manhole cost - usually 25% more than concrete construction. However, as the Packaged Metering Manholes are turn-key systems (and are not susceptible to Microbial Induced Concrete Corrosion (MICC)) single-source responsibility alone more than outweighs any difference in the initial costs.