What Goes Into a Composite (FRP) Packaged Manhole

At Openchannelflow we understand that not everyone who uses flow products does so on a regular basis. To help out the uninitiated or those needing a refresher, Openchannelflow has put together a series of blog articles covering the anatomy / nomenclature of our various flow products.

What Goes Into a Composite (FRP) Packaged Manhole covers the basic elements common to composite manholes, their identification, and usage.

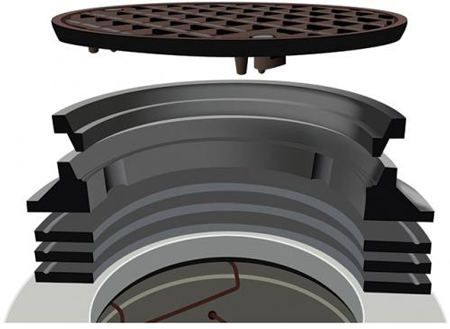

For a standard AASHO H-20 manhole:

Stack (usually supplied by the installing contractor)

A. Manhole Cover (or biscuit)

B. Manhole Cover Frame

C. Grade / Adjustment Ring(s) – used to bring the manhole cover to grade

Stack elements are typically steel (cover / frame) and concrete (rings). Composite construction is available from Openchannelflow when sold as part of a total manhole package. Stack elements are only required for Composite Manholes with AASHO H-20 reducers. Manholes with fiberglass domed tops or aluninum pedestrian hatches do not use stack elements.

Manhole Package

D. Ladder Assist – stainless steel quarter turn extension pole to aid in entering / exiting a manhole

E. Confined Space Entry Sign – OSHA compliant sign to reminder users of the potential dangers of confined spaces

F. Manhole Reducer with Shoulder – transitions the load from the grade ring / frame / cover stack to the manhole barrel walls

G. Manhole Barrel – built to meet or exceed ASTM D3753 “Standard Specification for Glass-Fiber-Reinforced Polyester Manholes and Wetwells”

H. Ladder – stainless steel reinforced, OHSA compliant, fiberglass (FRP) ladder with non-slip treads

I. Structure – flow element (flume, weir, mag meter), grinder channel, energy absorber, storm water screen, or diversion channel

J. Closed Base – for watertight construction

K. External Base Mounting Flange – to secure the manhole to a concrete pad

L. End Connection – pipe stubs, flanges, or caulking collars to direct flow into / out of the manhole

Composite (FRP) Manholes are single-piece, factory integrated, light weight, and corrosion resistant. They can integrate structures that stick out upstream / downstream of the manhole barrel. They require minimal installation time and are designed for exceptionally long service lives.