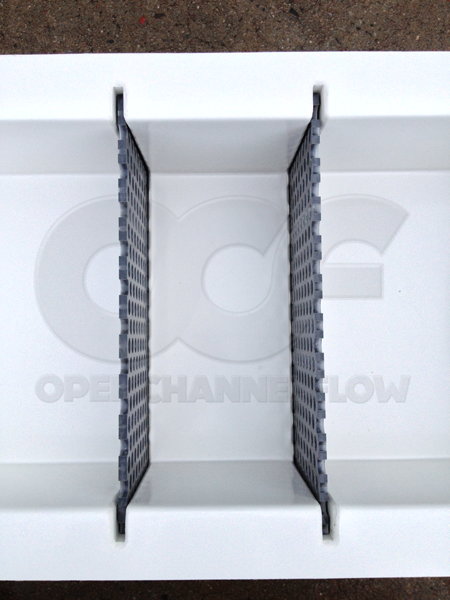

For flume and weir applications where the flow entering the device may not be as well distributed as one would like / or where the velocity profile needs adjustment, perforated baffle plates can be a good choice.

Used in a series of two or more, perforated baffle plates help break up the velocity profile and dampen turbulence in the flume.

The plates are fabricated from high-strength, abrasion resistant PVC, the plates slide into/out of recessed cavities molded into the walls / floor of the flume or weir.

Staggered hole patterns, both on the sheets and between the sheets, provide maximum flow straightening and provide an open area of 48%.

As with any PVC product, the maximum operating temperature of perforated baffle plates is 140° F [60° C], so for higher temperature applications, Openchannelflow provides stainless steel tranquiilzing racks.

Perforated baffle plates are designed for moderate flow conditioning and small spans. For larger spans, or where the inlet flow is more energetic or turbulent, stainless steel tranquilizing racks are a good flow conditioning choice.