Stilling wells are chambers isolated from, but connected to, the main flow of water in a flume, weir, or channel. Isolating the stilling well from the main flow via a small connector dampens or quiets the body of water in stilling well, while still allowing it follow the steady rise / fall of water in the main channel. Waves, surges, and turbulence commonly found in open channel flows are minimized. This minimization of non-flow related oscillations in the water level provides an excellent area in which to mount secondary flow meters (ultrasonic, float, bubbler, submerged probe).

Stilling wells are chambers isolated from, but connected to, the main flow of water in a flume, weir, or channel. Isolating the stilling well from the main flow via a small connector dampens or quiets the body of water in stilling well, while still allowing it follow the steady rise / fall of water in the main channel. Waves, surges, and turbulence commonly found in open channel flows are minimized. This minimization of non-flow related oscillations in the water level provides an excellent area in which to mount secondary flow meters (ultrasonic, float, bubbler, submerged probe).

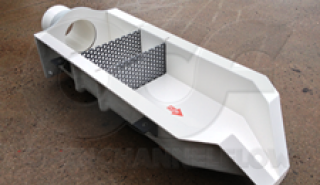

Floor Depression

The floor of a stilling well typically extends 3-inches [7.62 cm] below the zero elevation of the primary device (flume / weir). This depression means that water is present in the stilling well at all times – even when no flow is present in the flume / weir.

A benefit of this standing water is that parameter monitoring probes (typically pH, DO, and conductivity) can remain wetted. Be aware, though, that if flow does not refresh the standing water, that overtime parameter monitoring probes may experience reading drifts as conditions in the stilling well change (as has been directly observed with pH and DO probes).

The depression of the stilling well floor can cause problems with the accumulation of sediment and debris (as discussed below). Where sediment may be a concern, the floor of the stilling well can be made flush with the floor of the flume / weir. Note that by doing this, though, the usefulness of the stilling well at low flows will be greatly diminished.

Attached vs. Detached

Two styles of stilling wells are available: attached and detached. Attached stilling wells are molded or welded to the side of the flume or weir. Detached stilling wells are remote from the flume or weir and are connected to it via interconnecting tubing. Note that one difficulty in using attached stiling wells is when the sidewalls of the flume are not vertical (Trapezoidal and RBC). Here the stiling well can be no closer to the flume that the width of the top of the flume. For flumes like the Trapezoidal and RBC where the sidewalls expand outwards, the stlling well is moved further and further way from the connection at the bottom fo the flume. Effectively the stilling well is attached is name only.

Whether a stilling well is attached or detached, the connection between the flume / weir and the stilling well is typically a 2-inch [5.08 cm] opening. Openings may be larger or smaller depending upon need, but remember that for detached stilling wells far from the flume / weir, there is a lag between a change in the primary channel and a change in the stilling well. As the distance increases this lag becomes more prevalent – something a larger opening can help to alleviate.

Sizing a Stilling Well

The size of the stilling well primarily depends upon the type and configuration of the flow meter (secondary device) being used. The minimum size is that necessary to accommodate the flow meter sensor. In practice, tough, the need for maintenance should also be considered.

Standard stilling well diameters include:

- 6-inch [15.24 cm]

- 8-inch [20.32 cm]

- 12-inch [30.48 cm]

- 16-inch [40.64 cm]

When sizing stilling wells there are two points to remember. First, for ultrasonic flow meters the pulse of sound that emanates from the sensor spreads out in a cone. Sensors with wide beam angles or large deadbands may end of sensing the sidewalls of the stilling well before they sense the surface of the water. Second, as flumes / weirs get deeper stilling wells should correspondingly get larger. There is nothing worse than trying to unclog a 4’ deep, 8-inch [20.32 cm] stilling well. It’s the sort of thing you only want to do once.

When using a shaft encoder with a float, it is recommended to have 2-inches [5.08 cm] of clearance from the float to the stiling well walls.

Sanitary Flows

Stilling wells are never recommended for use on sanitary applications. Solids will always deposit in the stilling well and cause a source of ongoing maintenance and potential source of error. In particular, the connection from the flume / weir to the stilling well is prone to clogging is sanitary solids – even more so if the stilling well is remove from the flume / weir. The need for constant maintenance is the leading contributor to the abandonment of stilling wells in sanitary applications.

Sedimentation

As discussed above, stilling wells should never be used with sanitary solids. In addition, they should also be used with care on flow stream with high suspended solids. The reason for this is simple: stilling wells do exactly what their name implies – still the water. If they must be used on flow stream with high suspended solids, the stilling well should be sized large enough to allow for easy maintenance.

Also, where potable water is available, a purge / cleanout line can be run to the bottom of the stilling well to pulse water into the bottom of the stilling well. This pulsing can resuspend the accumulated solids; allowing them to exit the stilling well as the water in the well refreshes.

Cold Weather Flows

In applications where freezing weather may occur, it is often necessary to take certain measures to keep a stilling well free of ice. This is usually accomplished by one of two methods: electric immersion heaters or a layer of oil on the surface of the water in the stilling well.

Although they work well, immersion heaters require a power source to run them - something not always available at remote installations. Also, if the stilling well experiences no flow conditions for an extended period of time, the immersion heater can gradually evaporate the water standing in the stilling well – potentially exposing the immersion heater.

The other method of keeping a stilling well free of ice is a layer of oil on the surface of the water in the stilling well. This method works well, but care should be taken to ensure that the “zero” level for flow is based upon the level in the flume / weir itself and not in the stilling well (as the oil is on top of the water in the stilling well – adding height). Also, if the stilling well is expected to experience periods of no flow, the inlet for the stilling well must be below the zero elevation of the flume / weir. Otherwise the oil may drain out of the stilling well under low flow conditions.